Kev Siv Tau Roj Refining Txheej Txheem: Dej Degumming

Product Description

Degumming txheej txheem nyob rau hauv cov roj refining nroj tsuag yog tshem tawm cov pos hniav impurities nyob rau hauv cov roj crude los ntawm lub cev los yog tshuaj txoj kev, thiab nws yog thawj theem ntawm cov roj refining / purification txheej txheem. Tom qab ntsia hlau nias thiab hnyav rho tawm los ntawm oilseeds, cov roj crude mas muaj triglycerides thiab ob peb tsis-triglyceride. Cov uas tsis yog-triglyceride muaj xws li phospholipids, proteins, phlegmatic thiab qab zib yuav hnov mob nrog triglycerides los tsim colloid, uas yog hu ua cov pos hniav impurities.

Cov pos hniav impurities tsis tsuas yog cuam tshuam rau kev ruaj ntseg ntawm cov roj tab sis kuj cuam tshuam cov txheej txheem ntawm cov roj refining thiab sib sib zog nqus ua. Piv txwv li, cov roj uas tsis yog-degummed yog ib qho yooj yim los tsim cov roj emulsified nyob rau hauv cov txheej txheem alkaline refining, yog li ua rau muaj kev nyuaj ntawm kev ua haujlwm, roj refining poob, thiab kev siv cov khoom siv; nyob rau hauv cov txheej txheem decolorization, cov roj uas tsis yog-degummed yuav ua rau kom noj cov adsorbent thiab txo cov nyhuv discoloring. Yog li ntawd, tshem cov pos hniav yog tsim nyog raws li thawj kauj ruam hauv cov txheej txheem roj refinery ua ntej roj deacidification, roj decolorization, thiab roj deodorization.

Cov txheej txheem tshwj xeeb ntawm degumming suav nrog hydrated degumming (dej degumming), acid refining degumming, alkali refining method, adsorption method, electropolymerization thiab thermal polymerization method. Nyob rau hauv edible roj refining txheej txheem, feem ntau siv txoj kev yog hydrated degumming, uas muaj peev xwm rho tawm cov hydratable phospholipids thiab ib co non-hydrate phospholipids, thaum cov uas tsis yog-hydrate phospholipids yuav tsum tau muab tshem tawm los ntawm acid refining degumming.

1. Kev ua haujlwm ntawm hydrated degumming (dej degumming)

Cov roj crude los ntawm cov txheej txheem tshem tawm cov kuab tshuaj muaj cov dej-soluble Cheebtsam, feem ntau muaj phospholipids, uas yuav tsum tau muab tshem tawm los ntawm cov roj kom pab tau qhov tsawg kawg nkaus los nag thiab nyob rau lub sij hawm thauj roj thiab khaws cia ntev. Cov pos hniav impurities xws li phospholipids muaj cov yam ntxwv ntawm hydrophilic. Ua ntej tshaj plaws, koj tuaj yeem do thiab ntxiv cov dej kub los yog cov tshuaj electrolyte aqueous xws li ntsev & phosphoric acid rau cov roj kub kub. Tom qab ib lub sij hawm cov tshuaj tiv thaiv, cov pos hniav impurities yuav condensated, subsided thiab tshem tawm los ntawm cov roj. Hauv cov txheej txheem hydrated degumming, cov impurities feem ntau yog phospholipid, nrog rau ob peb cov protein, glyceryl diglyceride, thiab mucilage. Dab tsi ntxiv, cov pos hniav uas tau muab rho tawm tuaj yeem ua tiav rau hauv lecithin rau zaub mov, tsiaj pub lossis rau kev siv.

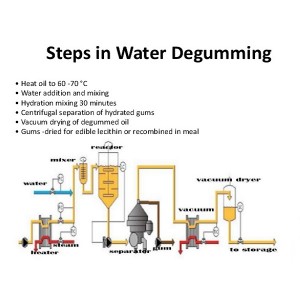

2. Cov txheej txheem ntawm hydrated degumming (dej degumming)

Cov txheej txheem dej degumming suav nrog ntxiv dej rau cov roj crude, hydrating cov dej soluble Cheebtsam, thiab ces tshem tawm feem ntau ntawm lawv ntawm centrifugal sib cais. Lub teeb theem tom qab kev sib cais centrifugal yog cov roj degummed, thiab cov theem hnyav tom qab kev sib cais centrifugal yog kev sib xyaw ua ke ntawm dej, dej soluble Cheebtsam thiab entrained roj, collectively hu ua "cov pos hniav". Cov roj crude degummed yog qhuav thiab txias ua ntej xa mus rau cia. Cov pos hniav yog nqus rov qab rau ntawm pluas noj.

Hauv cov roj refining cog, lub tshuab hydrated degumming tuaj yeem ua ke nrog cov roj deacidification tshuab, decolorization tshuab, thiab deodorizing tshuab, thiab cov cav tov no yog cov muaj pes tsawg leeg ntawm cov roj purifying ntau lawm kab. Cov kab purifying yog muab faib ua hom sib tshuam, hom semi-nruab nrab, thiab hom txuas ntxiv. Cov neeg siv khoom tuaj yeem xaiv hom raws li lawv qhov yuav tsum tau muaj peev xwm tsim tau: lub Hoobkas nrog lub peev xwm ntau lawm ntawm 1-10t ib hnub twg yog qhov tsim nyog rau kev siv cov khoom siv sib cuam tshuam, 20-50t ib hnub lub Hoobkas tsim nyog siv cov khoom siv ib nrab txuas ntxiv, tsim ntau tshaj 50t ib hnub twg yog qhov tsim nyog rau kev siv cov khoom siv tas li. Hom kev siv ntau tshaj plaws yog qhov sib cuam tshuam hydrated degumming ntau lawm kab.

Technical Parameter

Lub ntsiab yam tseem ceeb ntawm Hydrated degumming (dej degumming)

3.1 Qhov ntim ntawm cov dej ntxiv

(1) Cov nyhuv ntawm cov dej ntxiv rau ntawm flocculation: Cov dej kom tsim nyog tuaj yeem tsim cov txheej txheem liposome ruaj khov. Cov dej tsis txaus yuav ua rau cov dej tsis tiav thiab tsis zoo colloidal flocculation; Cov dej ntau dhau tuaj yeem tsim cov dej-roj emulsification, uas nyuaj rau cais cov impurities ntawm cov roj.

(2) Kev sib raug zoo ntawm cov ntsiab lus dej ntxiv (W) thiab cov ntsiab lus glum (G) hauv qhov sib txawv ntawm kev ua haujlwm kub:

| Tsis tshua muaj dej kub (20 ~ 30 ℃) | W = (0.5 ~ 1) G |

| Nruab nrab kub hydration (60 ~ 65 ℃) | W = (2 ~ 3) G |

| kub hydration (85 ~ 95 ℃) | W = (3-3.5)G |

(3) Kev sim ua qauv: qhov tsim nyog ntawm cov dej ntxiv tuaj yeem txiav txim siab los ntawm kev sim ua qauv.

3.2 Ua haujlwm kub

Kev ua haujlwm kub yog feem ntau sib xws rau qhov ntsuas kub tseem ceeb (rau qhov zoo dua flocculation, kev ua haujlwm kub tuaj yeem siab dua qhov kub tseem ceeb). Thiab qhov kev ua haujlwm kub yuav cuam tshuam rau cov dej ntxiv thaum qhov kub thiab txias, cov dej loj, txwv tsis pub, nws yog me me.

3.3 Kev sib xyaw ntawm cov dej sib xyaw thiab cov tshuaj tiv thaiv lub sijhawm

(1) Inhomogeneous hydration: Gum flocculation yog cov tshuaj tiv thaiv heterogeneous ntawm kev sib cuam tshuam. Txhawm rau tsim cov roj-dej emulsion lub xeev ruaj khov, kev sib xyaw ua ke ntawm cov khoom sib tov tuaj yeem ua rau cov tee dej tawg tag nrho, kev sib xyaw ua ke yuav tsum muaj zog tshwj xeeb tshaj yog thaum cov dej ntxiv loj thiab qhov kub thiab txias.

(2) Kev sib xyaw ntawm hydration: Thaum sib xyaw cov roj nrog dej, qhov sib tov ceev yog 60 r / min. Thaum lub sij hawm ntawm flocculation generating, stirring ceev yog 30 r / min. Lub sijhawm tshuaj tiv thaiv ntawm hydration sib tov yog nyob ib ncig ntawm 30 feeb.

3.4 Electrolytes

(1) Ntau hom electrolytes: ntsev, alum, sodium silicate, phosphoric acid, citric acid thiab dilute sodium hydroxide tov.

(2) Lub luag haujlwm tseem ceeb ntawm electrolyte:

a. Electrolytes tuaj yeem cuam tshuam qee qhov hluav taws xob ntawm cov khoom siv colloidal thiab txhawb cov colloidal hais kom sedimentate.

b. Txhawm rau hloov cov tsis-hydrated phospholipids rau hydrated phospholipids.

c. Alum: flocculant pab. Alum tuaj yeem nqus cov xim hauv cov roj.

d. Txhawm rau chelate nrog hlau ions thiab tshem tawm lawv.

e. Txhawm rau txhawb cov colloidal flocculation ze dua thiab txo cov roj cov ntsiab lus ntawm flocs.

3.5 Lwm yam

(1) Cov roj sib xws: Ua ntej hydration, cov roj crude yuav tsum tau nplawm tag nrho kom cov colloid tuaj yeem faib sib npaug.

(2) qhov kub ntawm cov dej ntxiv: Thaum hydration, qhov kub ntawm cov dej ntxiv yuav tsum sib npaug los yog siab dua me ntsis ntawm cov roj kub.

(3) Ntxiv dej zoo

(4) Kev ua haujlwm ruaj khov

Feem ntau hais lus, kev tsis sib xws ntawm cov txheej txheem degumming yog txiav txim siab raws li qhov zoo ntawm cov roj, thiab qhov tsis sib txawv ntawm cov roj sib txawv hauv cov txheej txheem degumming yog txawv. Yog tias koj muaj kev txaus siab rau cov roj refining, thov hu rau peb nrog koj cov lus nug lossis tswv yim. Peb yuav npaj peb cov kws tshaj lij engineers los kho cov kab tsim roj uas nruab nrog cov khoom siv roj refining rau koj.